Innovation

Innovation is deeply ingrained in Marel’s culture and is one of our core values. To continuously build our ability to connect and transform our industry, we invest 6% of our annual turnover into innovation activities.

Our commitment to innovation is driven by our aim to create a sustainable food processing industry, where precious resources are used responsibly and food waste is minimized. By pursuing this goal, we enable our customers to remain adaptable, efficient and competitive.

In 2022, Marel brought 33 new solutions to market, and we had the opportunity to engage with customers worldwide in person once again. We were able to showcase over 35 products that we had developed during the pandemic, displaying our achievements from the past year and a half.

Innovating in uncertain times

We innovate solutions that align with the major trends we observe in the food processing industry, including the growing demand for automation, digitalization, sustainability and integrated line concepts. Our dedication to these areas is reflected in this past year’s innovation launches, which are highlighted at the end of this chapter.

We strive to help food processors adapt to a changing world. As consumer preferences shift toward more ready-made meals and complex retail offerings, our customers are also facing labor scarcity and rising costs of raw materials and energy. To help them meet these challenges and supply consumers with sustainably produced, high-quality food, we must embrace new technologies and processes at an increasing pace.

To support our customers, we aim to connect them with their processes, transform the technology base on which they operate and innovate our way to better solutions. Our efforts are focused on key areas such as connectivity, automation, sustainability and flexible line offerings.

Automation

As a megatrend in the food processing industry, automation is key to Marel’s innovation efforts. Through the development of automation, robotization and digitalization, Marel helps food processors create opportunities to improve food safety, sustainability, efficient resource use and animal wellbeing. These cutting-edge technologies also reduce dependence on manual labor and make processing lines more flexible.

Connectivity and digitalization connecting to service

In 2022, we are proud to have transitioned from extensive planning to live implementation in our digital journey. We made solid progress on our roadmaps for the next connectivity products across all industries, for example with our SmartBase cloud solution.

We also continued our digital journey by developing new service products and digitally connected solutions in our current installed base, such as the SmartBase-enabled ModularOven. These efforts have positioned Marel at the forefront of the food processing industry, taking advantage of the latest advancements in automation and Industry 4.0.

Next-level line solutions

In recent years, Marel has worked closely with current and potential customers to initiate several product development programs specifically addressing innovative line concept solutions. In 2022, we introduced the Beef Steak Line to market at IFFA, which was a major milestone in taking our line solutions to the next level. The Beef Steak Line is just one of many solutions that address ease of integration, standardization and modularization, all of which improve costs and lead time to market.

Case study:

Expanding the FleXicut range

Marel has launched two new FleXicut models for portioning salmon and whitefish: FleXicut Tres and FleXicut Valka. The FleXicut range combines intelligent software, waterjet cutting and advanced X-ray capabilities to improve sustainability and profitability through higher yield and throughput.

FleXicut Tres

The FleXicut Tres is designed for skin-on and skinless large whitefish and pre-rigor salmon fillets, enabling maximum raw material utilization. The X-ray scanning area fits large fillets and detects bones as small as 0.2 mm, with advanced software adjusting cutting angles to remove bones and optimize efficiency.

The solution uses dual-cutting technologies, with three waterjets making curved and angled cuts, and twin blades making vertical cuts. This combination improves flexibility and prioritizes high-value portions. Cutting patterns can be easily adapted to suit market trends, helping customers remain competitive.

FleXicut Valka

The FleXicut Valka helps drive fish processing toward a more profitable and sustainable future. Developed following Marel’s bolt-on acquisition of Valka, this advanced machine combines software and robotics for extreme flexibility and precise deboning of skin-on or skinless salmon and whitefish.

A 3D vision system scans fillet size, shape and density, while a high-definition X-ray detects even the smallest bones. Fillets are then precision deboned and portioned using tilted and dynamic waterjet robot cutters that can cut at any angle or curved pattern, maximizing yield and thus the value of the end-product.

New Automation Center to support faster innovation to market

In 2022, Marel Innovation formally established the Automation Center—a decentralized virtual team dedicated to nurturing and further developing the necessary collaboration between our experts within robotics, computer vision and artificial intelligence (AI). The aim is to provide and combine expert knowledge, continuously keep on-trend with new technology and provide development teams with relevant building blocks to create smarter solutions for our customers.

Did you know?

Marel Incubator process to support proof-of-concepts

When working with cutting-edge technology, Innovation often needs to mature ideas and concepts, transfer knowledge from universities and test out the latest offerings from our suppliers. To support these activities, we have established the Marel Incubator process for conducting proof-of-concept studies. The Automation Center will build and maintain test labs where we will perform these studies and test out new technology.

Core team of experts

To maintain Marel’s leadership in advanced technology offerings, the core team of the Automation Center is responsible for investigating, integrating and maintaining new technology. Additionally, the team is responsible for fostering a knowledge-sharing community by hosting expert forums, presentations and company-wide information sharing that is released bi-annually.

AI and computer vision platforms

The center’s core team develops and maintains platforms for AI and computer vision, which focuses on enabling machines to interpret and understand the visual world. A common platform ensures faster innovation, a higher quality and scalable solution, and improved ways of working. The platform provides common building blocks for all development teams that seek to implement computer vision and/or AI into their solutions.

Automating flexibility with an emphasis on line solutions

Marel has come a long way in automating primary processing but faces the challenge of balancing automation and flexibility in secondary processing. Since processors in the retail and foodservice sectors must cater to a high variety of consumer preferences and cope with a scarcity of labor, flexibility is crucial. Our experts are working to address this issue throughout the company.

Automation opportunities in a customer-driven value chain

With emerging technology and new channels such as e-commerce, the industry is trending toward a customer-pull-driven value chain, where the end-consumer creates the food processing requirements.

Based on our engagement with customers, we have identified a clear need and demand for advanced interlinked secondary processing steps in the value chain. We aim to simplify our offering of line solutions, accelerate key integration developments and fully utilize automation opportunities to achieve this goal.

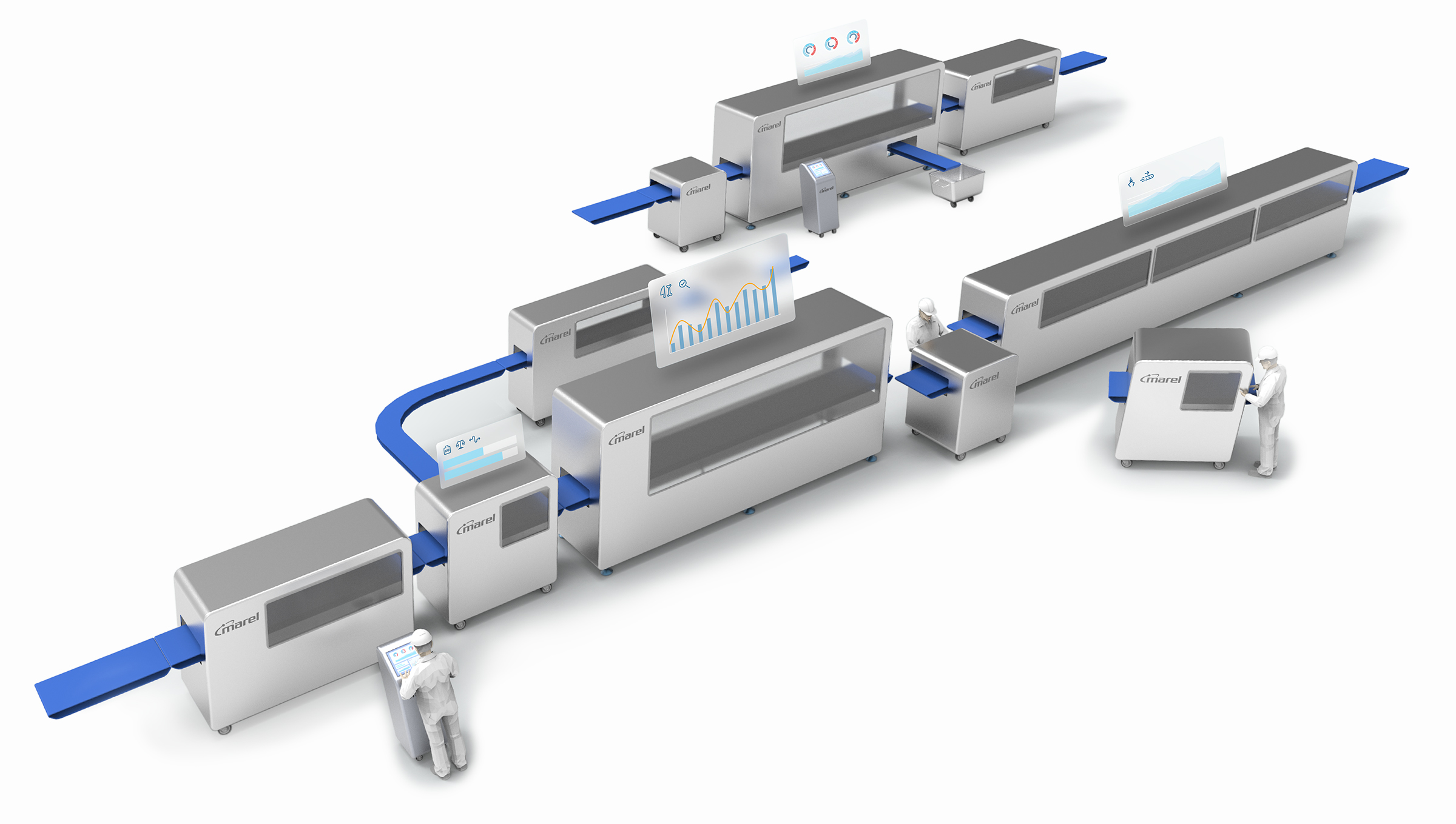

Automating across business divisions to benefit customers

To further enhance our customers’ experience, we are prioritizing the development of global standards for mechanical, electrical and digital environments throughout Marel. We are also creating integrated and connected line solutions for our customers. By doing this, we will be able to deliver fully flexible and modular sub-systems and end-to-end line solutions, as illustrated below.

Enabling our customers to be connected creates added value and serves as an additional incentive to view Marel as a one-stop shop for aftermarket services, trusted maintenance partnerships, and digital connectivity in service.

A conceptual example of future line flexibility

Sustainability in Innovation

In 2022, we made great strides in advancing our sustainability efforts. We began by mapping out ongoing initiatives across the company that could be having a positive impact on Marel’s sustainability goals. From this assessment, we identified several areas for continued monitoring, two of which have a direct impact on the company’s overarching sustainability key performance indicators: the Sustainability Scorecard 2.0 and Product Life Cycle Analysis. These initiatives also support our Innovation Roadmap focus, illustrated below.

Sustainability Scorecard 2.0

Marel has developed the Sustainability Scorecard 2.0 to make sustainability a permanent criterion for evaluating all new product developments (NPDs) at every stage of our development process. The scorecard, updated from the previous Sustainability Scorecard, helps our innovation team focus on improving sustainability in the food value chain, ensuring that all Marel innovations align with our goals in this area. In 2022, all new innovation projects approved for further development were rated using the scorecard, maintaining our 100% rating from 2021.

Sustainability through extended reality and simulations

In 2022, we made progress in utilizing extended reality (XR) and other simulations to improve our sustainability impact. Our engineering innovations have reduced waste of raw materials in the prototyping phase by increasing the use of virtual prototyping. Additionally, we have reduced the need for shipping equipment to exhibitions by using 3D real-time immersive technology to showcase our innovations. This technology is shown in action in the video below.